Novacel, the worldwide leader of Laser protective films

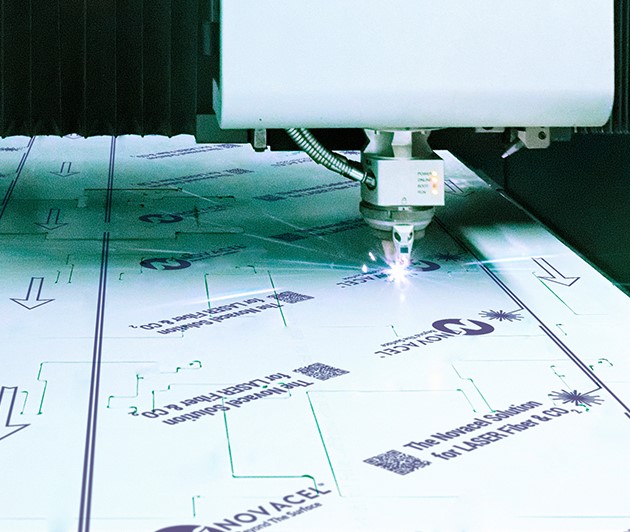

In a manufacturing environment, precision and efficiency drive success. Novacel’s films are meticulously engineered to optimize the laser cutting of metals (stainless steel, aluminum, copper, brass, coated metal….) and other materials, safeguarding the integrity of the surface while improving the cutting accuracy and speed.

Benefits of Novacel processing and protective films for Laser Cutting

The Laser Cutting process is a demanding one. It was the case with the old CO² technology and remains such with the newest fiber capabilities. The processing and protective films required for this process need to be resilient. Appropriate Laser absorption and resistance to cutting gas pressure are always the main prerequisites for Laser Cutting film.

Reliability is the key word. The Novacel Laser films ensure productivity and quality of LASER processes. Indeed, using Novacel films ensure the cutters:

- Secure protection of metals, especially for stainless steel

- Preservation of their integrity

- Cutting in one step, and at full speed

- No bubbling, minimal shrinkage, accurate film edges

- No surface marking, peel-off in one piece

- Premium adhesion for reliability during the process

- Outdoor resistance (up to 6 months)

Why choose Novacel for Laser Cutting?

Novacel is the worldwide leader in laser cutting solutions. Thanks to years of experience, innovation and customers recommendations, Novacel offers the widest range on the market to meet all needs.

Superior Surface Solutions

Novacel’s processing and protective films are designed to prevent scratches and damage during the laser cutting process. This protection is crucial for maintaining the aesthetic and functional quality of high-value materials such as stainless steel, aluminum, copper, brass and coated metals.

Enhanced Cutting Performance

Thanks to their high absorption capacity of the laser wavelength, Novacel’s films ensure a cleaner and more precise cut in a single-step. This leads to a more efficient process with reduced waste and lower rework costs.

Customizable Solutions

Understanding that each material and laser cutting machine has unique requirements, Novacel offers customized film solutions tailored to specific needs. Whether you’re dealing with intricate designs or thick materials, Novacel has a film solution that can enhance your cutting process.

Eco-Friendly Options

In response to growing environmental concerns, Novacel is committed to providing eco-friendly film solutions that are recyclable and made from sustainable resources. These efforts contribute to a greener manufacturing process and align with global sustainability goals.

Discover our processing and protective films

for Laser cutting

How do Novacel films work when used for Laser Cutting?

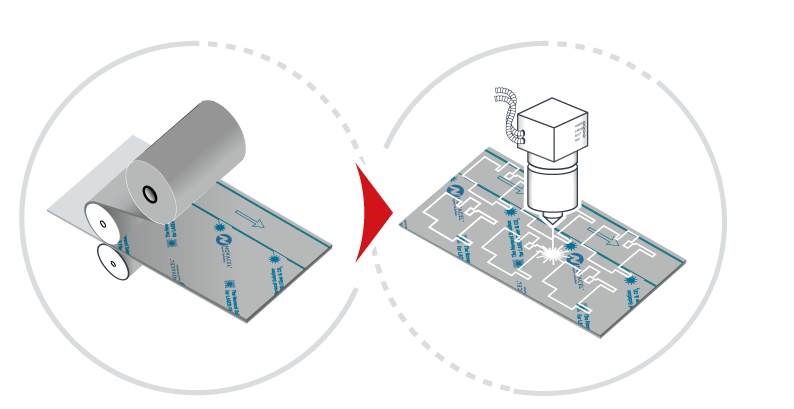

Laser cutting processing and protective films, also known as a laser cutting mask or laser cutting tapes, serves as a temporary layer on materials during the laser cutting process. It acts as an indispensable second skin in a laser cutting process. Without it, laser cutting would not be possible. It prevents damage or contamination of the material's surface and ensure precise and clean laser cuts. Novacel assists you from the choice of your process and protective film for laser cutting, right through to its removal.

How to apply laser cutting processing and protective films?

Applied on the surface to be cut, the film acts as a shield, preserving the material from potential damage during the laser cutting process.

To apply the processing and protective film, start by thoroughly clean the material and remove any grease, oil, or residues that could interfere with adhesion. Then, ensure that the surface is completely dry.

If you're using a laminating machine, it's essential to ensure its settings, beforehand, to ensure a perfect application of the laser cutting processing and protective film on the surface.

Once the protective film is in place, you can proceed with laser cutting.

Configure your laser equipment according to the specifications of the material and the type of laser film you're using. Conduct a preliminary test on a small piece to ensure the setup is correct. If the test is successful, continue with the laser cutting.

How to remove a laser cutting processing and protective film?

After completing the laser cutting, allow the material to cool, if necessary, and then remove the processing and protective film. Gently peel it off from one corner, pulling steadily but carefully. Finally, give the material a final cleaning to ensure it's debris-free.

Discover the key factors affecting film quality, and some practical tips to ease the removal.

Discover Novacel market's largest range of LASER films

Novacel's protective films for stainless steel are designed to prevent defects during manufacturing processes such as laser cutting and also for drilling, bending, and punching. These films offer stable adhesion, significant outdoor resistance (2 to 6 months), and easy removal without tearing. They protect against dirt, scratches, and tool marks, ensuring a flawless finish with no residue once removed.

All the range of LASER protective films

|

Grade |

Thickness (μm/mils) |

Adhesion |

Outdoor resistance |

Specific features |

|---|---|---|---|---|

| 4228REF |

100μm/3.9mils |

Very High |

6 months |

For all kinds of finishes |

| 4464RLN |

100μm/3.9mils |

Very High |

6 months |

Low Noise |

| 3030GAB |

100μm/3.9mils |

Very High |

6 months |

Oxygen Vegetal |

| 3300GAC |

100μm/3.9mils |

Very High |

6 months |

Oxygen Vegetal+ |

| 3200GAB |

100μm/3.9mils |

Very High |

6 months |

Oxygen Lean |

| 4188REF |

100μm/3.9mils |

Very High |

None |

Transparent |

| 4273RES |

105μm/4.1mils |

Ultra High |

6 months |

For textured finishes |

| 4329REH |

80μm/3.2mils |

High |

6 months |

For glossy and lightly brushed finishes |

| 4327RFA |

70μm/2.8mils |

High |

6 months |

For glossy and lightly brushed finishes |

| 4236RET |

60μm/2.4mils |

High |

6 months |

Perfect for coverage of sheet bottom side |

| 4318REM | 75μm/3.0mils | Medium | 6 months |

For glossy finishes on thin sheets (<1mm) |

All grades are grey or black films, except for 4188REF, which is a transparent film.

Thanks to our research laboratory, experts can analyze your surfaces in the finest detail and test how our films behave on your materials.

Laser Cutting films are available with the Low Noise functionality

To protect your operators against noise-induced stress during unwinding operations, Novacel has developed the Low Noise technology. It is a patented technology that is available in the range of films dedicated to the Laser Cutting operations.

Discover our range of Low Noise processing and protective films!

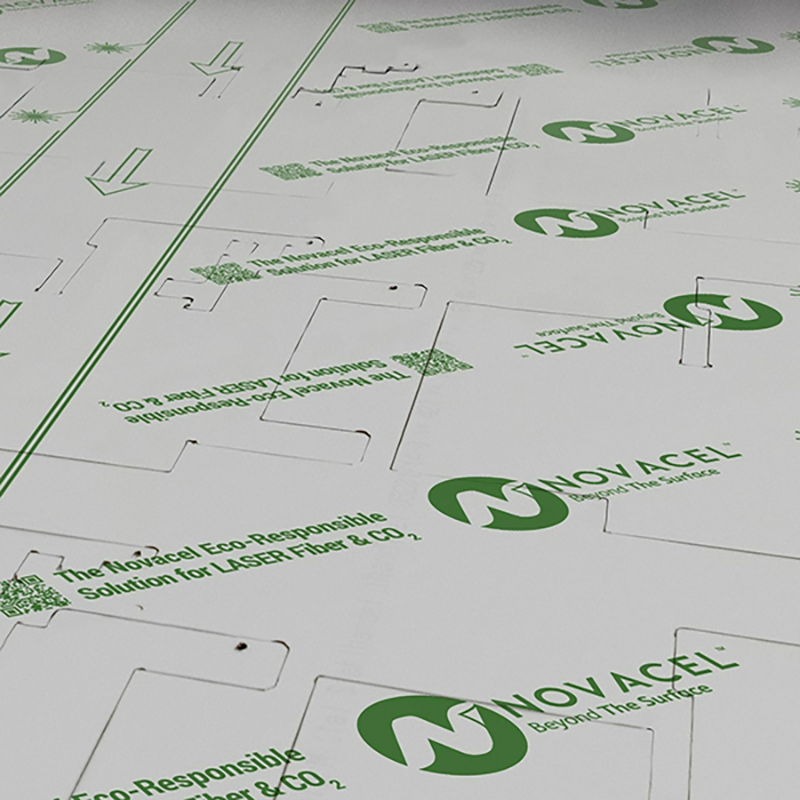

Novacel eco-responsible range for Laser cutting

![]()

Reducing the environmental impact of our products on the planet is a daily challenge. Novacel has developed a unique range of eco-responsible products dedicated to Laser cutting process : Oxygen Vegetal, Oxygen Vegetal+ and Oxygen Lean.

Discover our range of Oxygen processing and protective films