Process & protective films for ski manufacturing

The manufacture of a ski involves many steps. Whether it is a traditional, sandwich or injected ski, it is composed of several layers, the top layer being called the ‘Top Sheet’.

It is this top layer that must be protected by a film specially designed to maintain the quality and aesthetics of the ski during its manufacturing stages.

A solution dedicated to protecting top sheets

Novacel has developed a highly technical process and protective film that preserves the quality of top sheets made from thermoplastic polyurethane (TPU), polyamide (PA) or polyester (PET). Regardless of the material it is made from, the top sheet benefits from the following advantages:

Film transparency

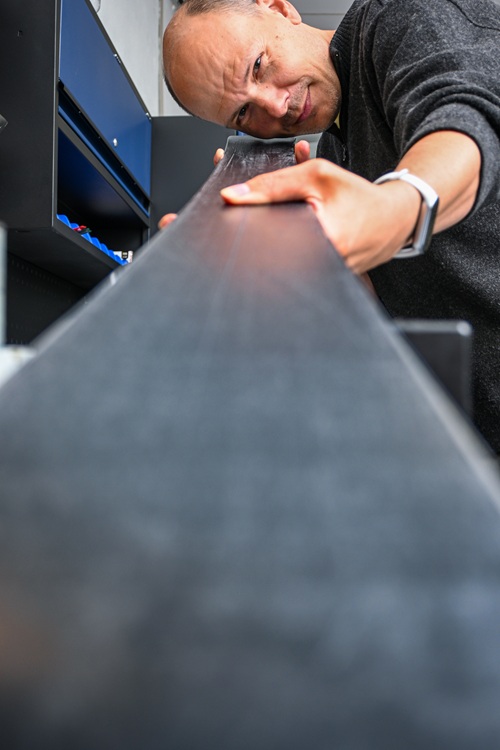

The transparency of the film allows the quality of the ski to be visually checked throughout the production process.

Application without stretching

The film is easily applied to the surface without stretching, thus preventing the surface from curling during printing, whether screen printing, sublimation or digital printing.

Resistance to high temperatures

Specially developed for sublimation, NOVACEL film withstands the high thermal stresses of the process, up to 160°C (320°F), while maintaining its performance.

Air evacuation from the manufacturing mould

After assembling all the components of the ski: the core, reinforcements, edges, sidewalls and base, the ski is moulded.

During this stage, the controlled roughness of the Novacel film allows air to escape from the mould without deforming the surface.

Increased resistance during demoulding, cutting, shaping and sanding.

Despite the presence of lubricant during these manufacturing stages, the adhesion of the Novacel film to the top sheet remains intact until it is removed.

Removal without breakage

While being highly resistant to all manufacturing stresses, the film can be removed without tearing, resulting in significant productivity gains during this final stage.

Meeting the needs of ski and snowboard manufacturers

To address the various issues faced by manufacturers, Novacel offers two types of process and protective films for top sheets, depending on their surface conditions and adhesion levels.

Novacel 9279

Novacel 9279 is suitable for application on thermoplastic polyurethane (TPU), polyamide (PA) or polyester (PET) topsheets with a glossy, smooth surface. It has a thickness of 120 μm (4.8 mils).

Novacel 9289

Novacel 9289 is suitable for application on thermoplastic polyurethane (TPU), polyamide (PA) or polyester (PET) top sheets with a textured and/or matt surface. It has a thickness of 130 μm (5.2 mils).

Both products are available in large widths up to 1520 mm and have an embossed structure specifically designed to evacuate air during ski moulding.

They are transparent, can be applied without stretching and are resistant to high temperatures.