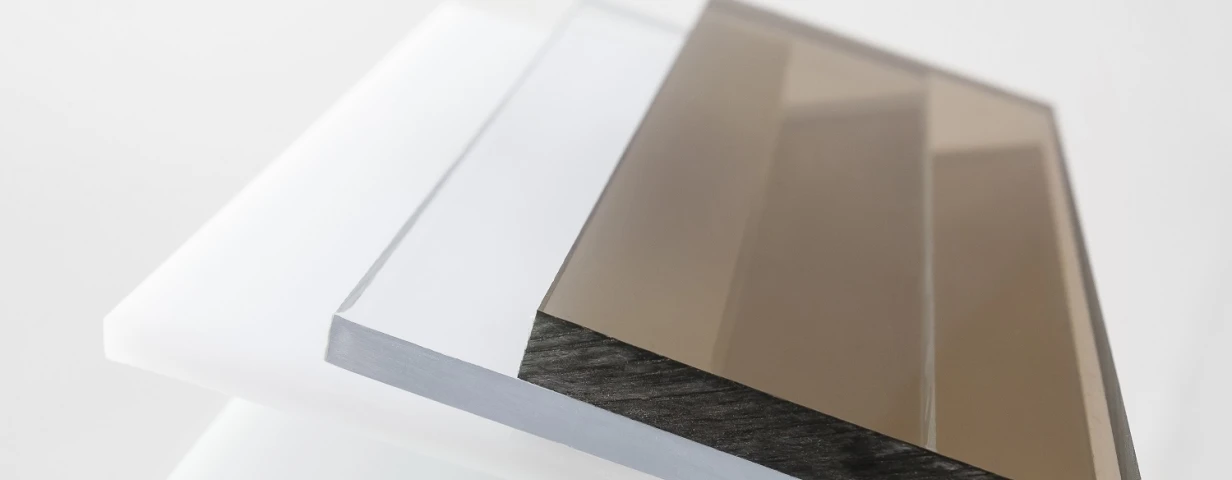

Processing and protective films for Polycarbonate (PC)

Polycarbonate film is a thermoplastic material with properties such as optical clarity, printability, impact strength, and dimensional stability. It also offers high temperature resistance and workability for secondary processes such as die cutting, embossing, and cold and hot forming.

Graphics, security and ID-cards, consumer electronics, automotive instrument and decoration are among its applications.

Most polycarbonate films are supplied with the masking film as standard to avoid damages during fabrication.

High performance requirements enhance the clarity of the surface, undergoing die cutting, printing and forming operations while keeping the polycarbonate film surface intact throughout.

Low gel content processing film, soft and stable adhesion and easy peel-off with no damage or curling of the surface are the main benefits of Novacel 9246 and Novacel 9078.

Polycarbonate film also comes in a variety of surface textures including gloss or polished, velvet, matt, and suede. For these, Novacel provides dedicated masking films with adhesion tailored to the finish of the PC surface.

Polycarbonate films can also improve their performance thanks to a specific coating giving increased scratch resistance, extended outdoor weatherability, and improved resistance to cleaning and industrial chemicals.

Optimum solution for polycarbonate sheets

Did you know that polycarbonate is 250 times as strong as standard glass while weighing only half as much?

Polycarbonate is so strong it is ideal for safety glazing, protective screens, skylights and domes, tunnels and greenhouse glazing.

It is an excellent choice for projects needing a high level of safety. Polycarbonate sheets are also available with a hard coating applied to improve their scratch resistance or offer additional UV characteristics.

It is an easy material to cut and fix. It can be formed into many shapes and sizes by thermoforming since it remains dimensionally stable over a wide temperature range. It also stands up well to cold curving and machining.

The large sizes of PC sheets make superior quality in the film essential to address the issues involved in high-value building.

Films for Polycarbonate: Tailor-made solution for each process

Novacel provides the best suitable solution, adapted to each process:

-

Novacel 9813 and Novacel 9816 coextruded films for safer thermoforming

- Novacel 4736 coated papers for severe machining processes

- Novacel 4768 coated film for sheets cut into small pieces with numerous operations.

There are even thick and highly engineered technical films with Novacel 9878 for abrasion-resistant polycarbonate sheets or for specific market requirements such as cutting-edge tapes for optical lens surfacing.