OXYGEN Lean: eco-friendly processing and protective films

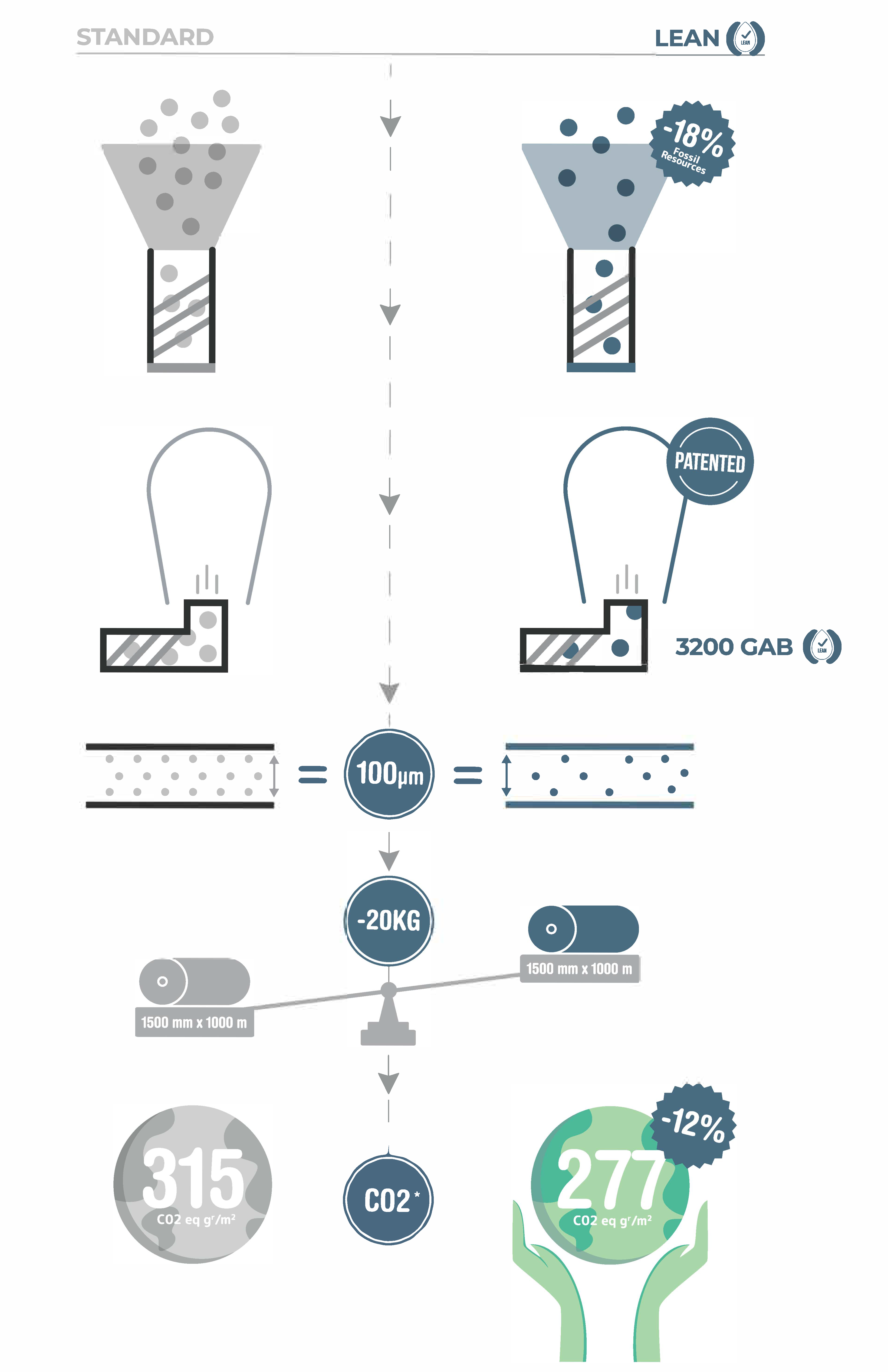

OXYGEN Lean films are the result of an innovative and patented extrusion process.

Thanks to this unique operation, it is possible to reduce the quantity of LDPE included in the film by 20% while keeping the same thickness.

With its range of OXYGEN Lean films, Novacel is committed to reducing the environmental footprint of films, but not only this.

~20 % LDPE reduction via a patented technology

The innovation of the Oxygen Lean range relates to its ability to provide a film of the same thickness as a traditional film while substantially reducing the percentage of fossil resources.

By reducing the quantity of LDPE, you act both on the carbon footprint of the product but also on its transportation (reduced thanks to the lightening of the rolls).

- CO² footprint reduction compared to a standard film

- Lighter rolls: reduce transportation weight & improve health and safety workers condition

It is therefore a powerful tool for simultaneously achieving technical and environmental goals.

![]()

Discover all the OXYGEN Lean processing and protective films!

OXYGEN Lean 3200GAB: dedicated to laser cutting

3200 GAB is based on the innovative patented LEAN extrusion technology. It brings you number of advantages:

- Lighter film rolls.

- For example, a 100kg roll will weigh only 80kg thanks to lean technology. As a result, the pallets are also lighter. This represents a reduction of 100kg for a 5 roll-pallet.

- Improved health and safety conditions for workers: lighter loads to be carried, fewer less back injuries.

- Enhanced carbon footprint

- Direct communication of environmental benefits on printable film.

- Recyclable*

Reserved for thick films, OXYGEN Lean technology is compatible with a multitude of surfaces: aluminium composite panels, metals, plastics, and can withstand the following transformation processes:

- Laser and fiber cutting

- Cutting and drilling

- Folding

- Stamping

* A list of approved recyclers is available in the Services section.

Recyclable by the forms of recycling as defined by ISO 472:2013 Plastics