Processing and Protective Films for Postforming

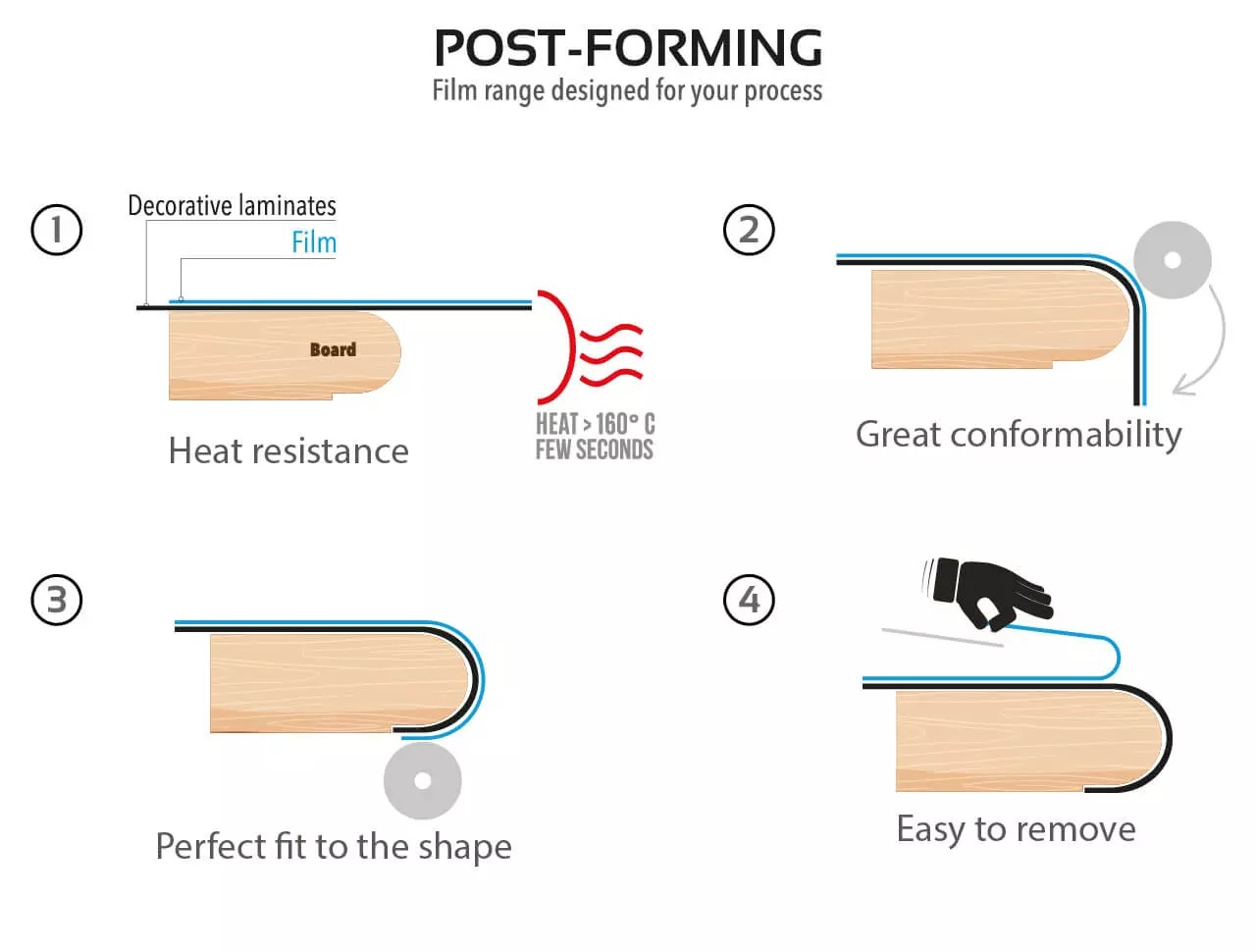

Some laminates are made with a special quality: thinner and more flexible, they can undergo “postforming” operations. Novacel's heat-resistant high quality films are designed to withstand the Postforming operations for the edge shaping of laminates while avoiding the risk of damage.

The postforming process for furniture

Among decorative laminates, there is a variety of HPL grades like standard, fire resistant, compact or postforming grades.

Post-forming describe the bending process applied to special laminate grades, thinner and more flexible, with excellent forming properties, which can be formed into curves.

Curved surfaces are more aesthetically pleasing than sharp edges on internal and external angles, eliminating joints in which dirt and water can accumulate.

Postforming operations require the laminate to be heated in the area in which it is to be formed, The decorative surface to be formed should be heated to a temperature of 165˚C to 190 ˚C (325 ˚F to 375 ˚F) for a few seconds depending on the thickness of the HPL.

Technical solutions dedicated to postforming

Novacel heat resistant processing solutions withstand the postforming process for the edge shaping while avoiding damage during and after the operation. Thanks to a specific polyester film designed with dedicated adhesive coating adjusted for each type of decorative finish, Novacel can offer the safest postformable solution of the market.

Novacel 9230 for high gloss postformable HPL, Novacel 4491 the versatile solution for most of finishes and Novacel 4496 for the critical one.

All Novacel dedicated postforming grades are stable in adhesion and well adapted to this technical operation.

Moreover, we put our expertise at your disposal to combine Novacel solution machine with the best selected film to end up to perfect lamination