Increase your visibility with the Trap Print technology

Film printing is part of Novacel's service offerings. By printing your logo, brand and even installation instructions, you turn your surface into a communication medium to increase your visibility and promote your corporate identity.

Novacel has developed innovative printing technology on its production lines: Trap print. This secure industrial solution is more environmentally friendly than standard printing with varnish and offers significant benfits when compared to traditional print processes.

Exclusively achievable on transparent films, it guarantees optimal protection of the print, which is shielded by the film.

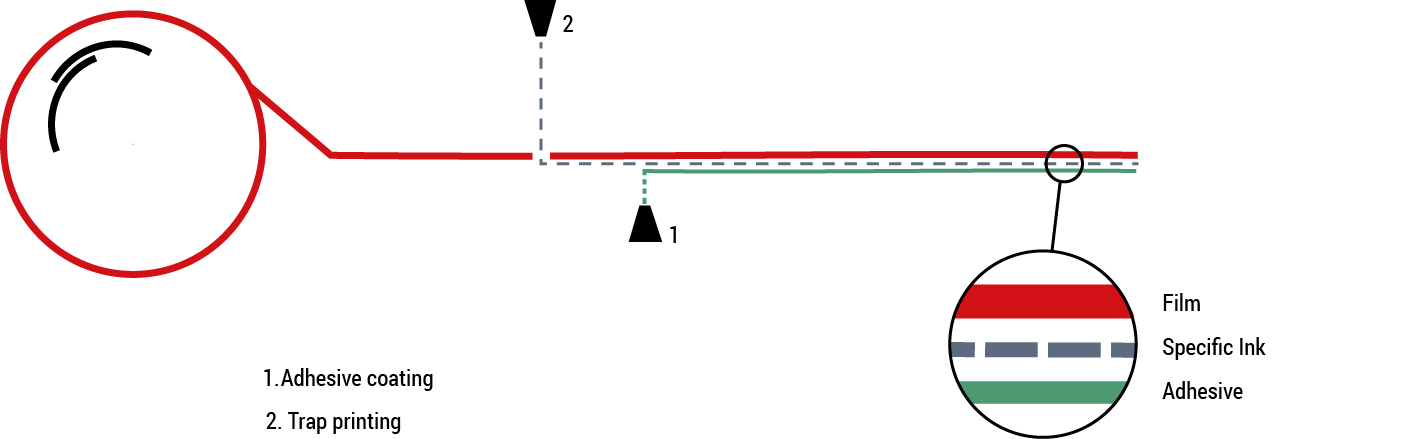

How does Trap print work?

Trap print technology

With trap print printing, the ink is inserted between the film and the adhesive layer. The film support completely preserves the print, even through aggressive fabrication processes.

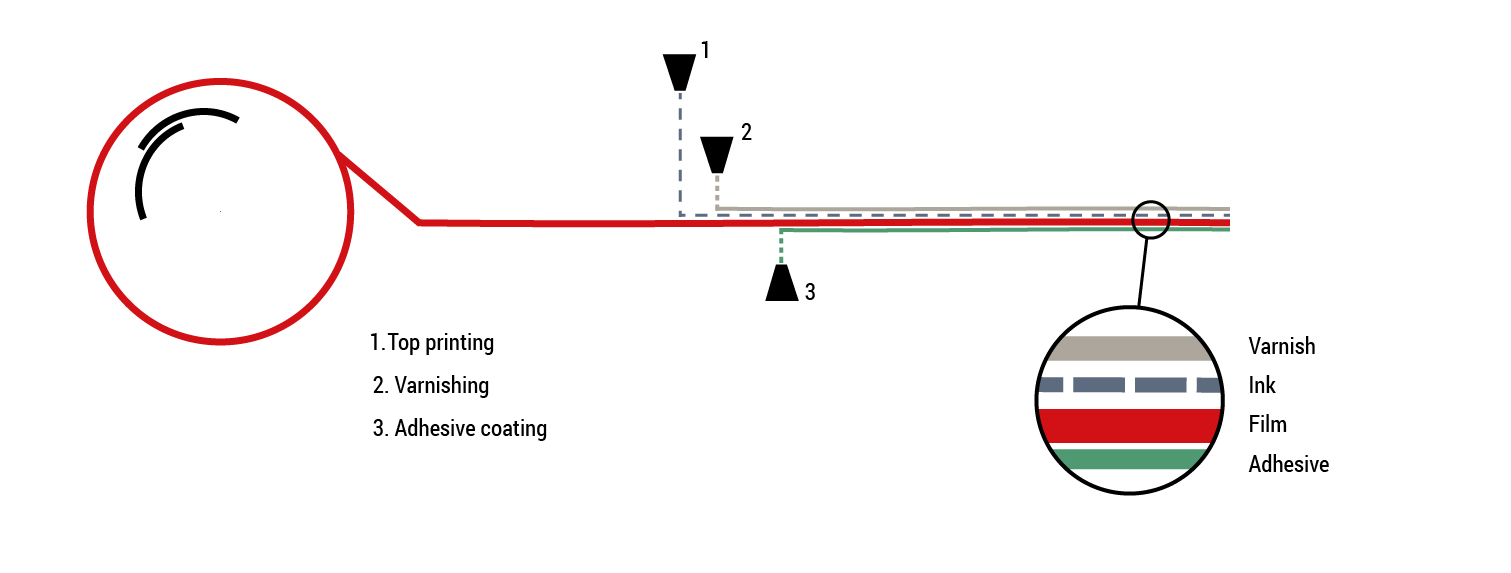

Standard printing technology

With standard printing, the ink is deposited on the film and requires protection by a varnish overlay.

An innovative and more sustainable printing

The Trap print technology eliminates the need for protective varnish and the solvents required for its application. This technology makes it a more ecological solution while maintaining the visual quality of the print.

The inks used for trap print have a specific premium formulation that ensures superior adhesion to the film.

Between the film and the adhesive layer, the ink cannot migrate, and there are no ink residues during manufacturing and conveying on automated fabrication lines.

Trap print preserves your industrial tools from dirt, reduces cleaning time, and lowers maintenance costs.

Critically the unique print process preserves the profile and corporate message from extrusion to installation.

Technical benefits of Trap print printing

Thanks to ink protection by the film, trap print proves to be 100% resistant to friction and to cleaning product solvents used at the end of production when cleaning the finished product.

Static electricity is significantly reduced with trap print printing, as it does not use varnish. Indeed, varnish overlays promote static electricity discharges due to friction of protected surfaces during conveying.

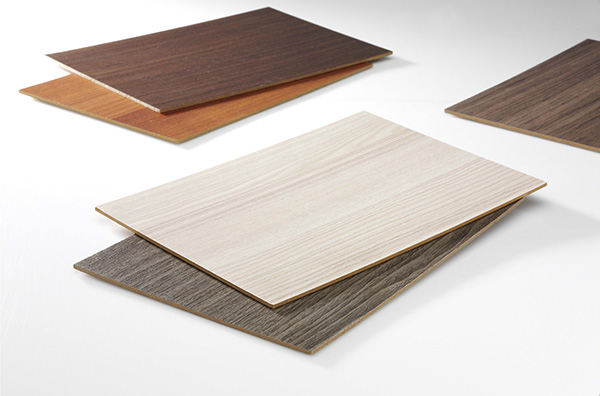

Novacel's films dedicated to window profiles and decorative laminates

Trap print technology applies to film for plastic profiles.

Novacel 9380 is a very high adhesive film with a thickness of 45 µm.

Its outdoor durability of 6 months is guaranteed without degradation of the print over time.

Decorative laminates can also benefit from Trap Print technology.

These materials undergo severe manufacturing constraints such as post-forming, bonding to wood panels, or bonding edge bands to panel edges.

Trap print technology facilitates the passage of decorative laminates on robotic lines without soiling or altering production tools with ink or varnish residues.

Novacel 9230 is an ideal solution for high-gloss post-formed decorative laminates. Thanks to its low adhesion, this film also offers Easy peel functionality!

Novacel 4514 is a highly adhesive film with a thickness of 57 µm. It also benefits from Low Noise technology.