Stainless Steel processing and protective films

Novacel films preserve the quality of your Stainless Steel, saving you from costly rework and preserving the integrity of your product.

Whatever the kind of Stainless Steel you process (brushed, glossy, mirrors…), Novacel films can help you maintain its quality even during the harshest manufacturing steps.

Novacel stainless steel films and tapes are more than just a solution - they are an assurance to succeed the manufacturing process of your Stainless Steel.

Why use Novacel processing and protective films on Stainless Steel?

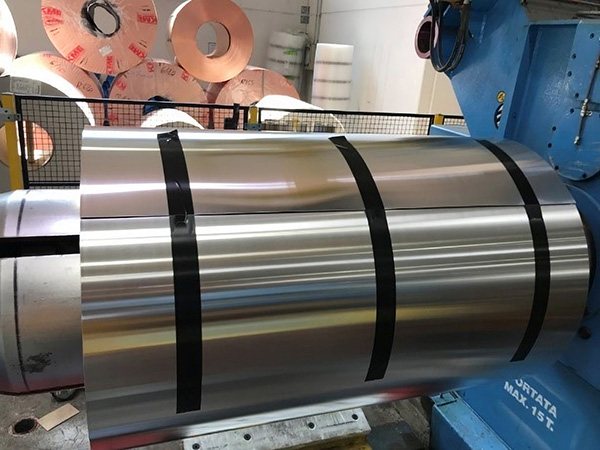

The manufacturing process from flat Stainless Steel coils or sheets to the final product is demanding. All the processes are harsh, involving heavy tools, heavy pressure and friction. They can result in surface impacts, dents and scratches that are unacceptable for your customers.

To avoid defects in your Stainless Steel throughout the entire manufacturing process, Novacel processing films are essential.

Novacel’s films enhance your efficiency and reduce costs

Surface damages can occur at any stage, leading to costly repairs or replacements that can significantly impact the profit margin. Using films contributes to a more stable supply chain, ensuring large bulk orders are fulfilled accurately and delivered on time without needing repairs.

Novacel’s films improve your customers’ satisfaction

Manufacturing processes performed using processing and protective films have less risk of damage when the product reaches the end user, keeping customers satisfied with undamaged goods.

Benefits of Novacel processing and protective films for Stainless Steel

-

Controlled adhesion: From a low to a very high level of adhesion, Novacel brings reliable solutions with stable and controlled adhesion throughout all processing cycles.

-

Easy Removal without tearing: with the appropriate film recommended by Novacel, your Stainless Steel surface will be preserved, leaving no residues, stains, or markings once the film is removed

-

Outdoor resistance: Up to 6 months, Novacel guarantees significant outdoor resistance for its films worldwide.

-

Suitable for every stainless steel surfaces: As an expert Novacel can provide films for every type of finishes such as glossy, brushed, structured, engraved, embossed, tinted, mill-finished, polished…

-

Available in many different thicknesses

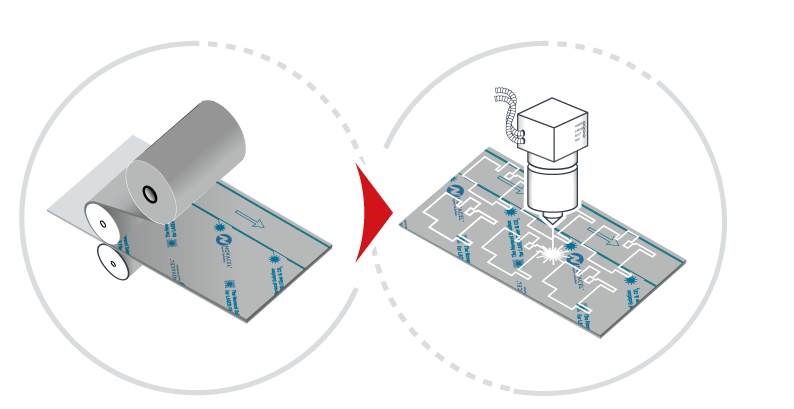

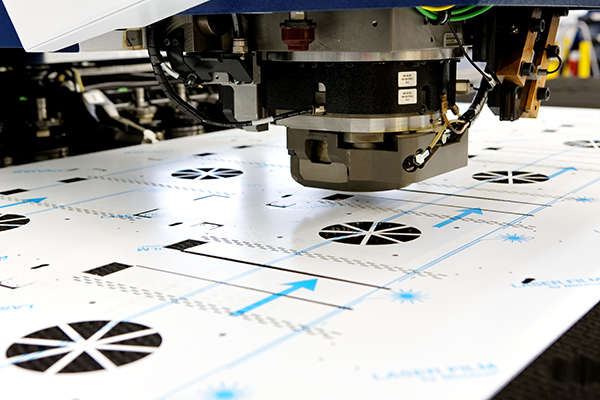

Novacel protective films for Stainless Steel laser cutting

Stainless Steel sheets are available in various finishes, each requiring a specific approach to the laser cutting process. Choosing the proper protective film tailored to the finish of your Stainless Steel sheet is crucial for optimal results.

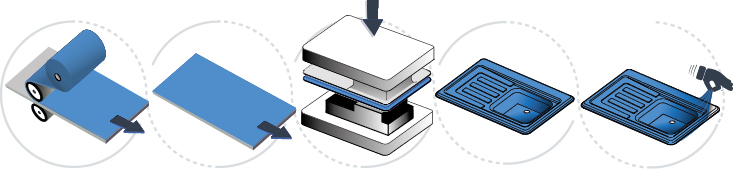

Novacel protective films for Stainless Steel Deep Drawing

The deep drawing process for Stainless Steel surfaces is one of the most common methods to shape sheets into finished products.

Novacel offers a unique range of PVC-free films with exceptional conformability that are specifically designed for deep-drawing applications.

Novacel is committed to helping you find the perfect match for every new shape or model you need to produce.

Novacel multipurpose films for Stainless Steel

Stainless Steel surfaces undergo numerous processes during the production of the final product, each with its unique characteristics, such as drilling, slitting, profiling, bending, punching, and stamping.

These processes subject Stainless Steel sheets and coils to high stress levels, potentially causing surface damage.

With Novacel's protective films, you can ensure that your Stainless Steel surfaces will arrive at your customer in pristine condition, free from scratches, scuffs, or soiling.

You can have peace of mind knowing that your surfaces will be protected throughout a variety of processes using Novacel's versatile solution.

Eco-conceived films for Stainless Steel

Driven by sustainability and involved in preserving the environement, Novacel is the first manufacturer to propose eco-conceived protective and protective films: The OXYGEN range.

![]()

Three technologies that enable you to reduce your carbon footprint are available for your Stainless Steel surfaces:

• The Vegtal+ technology: 80%* less carbon impact

• The Vegetal technology: 30%* less carbon impact

• The Lean technology: 12%* less carbon impact

*Minimum reduction based on certified LCIs (Life Cycle Inventories)

Novacel’s range of technical adhesive tapes for Stainless Steel

Novacel also offers a versatile range of technical adhesive tapes. These tapes are essential for securing metal coils during production and shipping, ensuring the safety of your staff and the protection of your products.

Metal Coil End Tabbing Tapes

Our single-sided adhesive tapes are designed explicitly for securing metal coils. They offer:

• Strong Adhesion

• High Tensile Strength

• Residue-Free Removal

Metal Overlap Splicing Tapes

For metal-manufacturing processes that require heavy stress and high-temperature resistance, our double-sided adhesive tapes provide:

• High Efficiency

• Durability

Metal Butt Splicing and Coil Core Starting Tapes

Our single-sided reinforced tapes are ideal for metal splicing and coil core starting applications, offering:

- High Adhesive Strength

- Reinforcement

Trust Novacel’s range of technical adhesive tapes for reliable, high-performance solutions in securing and handling Stainless Steel.

Stainless Steel: everything to know about this material

Stainless Steel, also known as inox, is a highly valued iron alloy renowned for its rust, corrosion, and staining resistance.

In the modern world, Stainless Steel has become indispensable. Its extensive use in applications ranging from architectural structures to everyday household appliances underscores its importance. However, manufacturing this robust material requires specialized solutions to ensure efficiency and quality.

Stainless Steel offers a range of surface finishes that meet different aesthetic and functional needs, such as matte, bright, brushed, engraved, embossed, or even tinted.

Novacel, as an expert in surface solutions, is committed to supporting the stainless steel industry by providing innovative solutions that facilitate the manufacturing of Stainless Steel products.