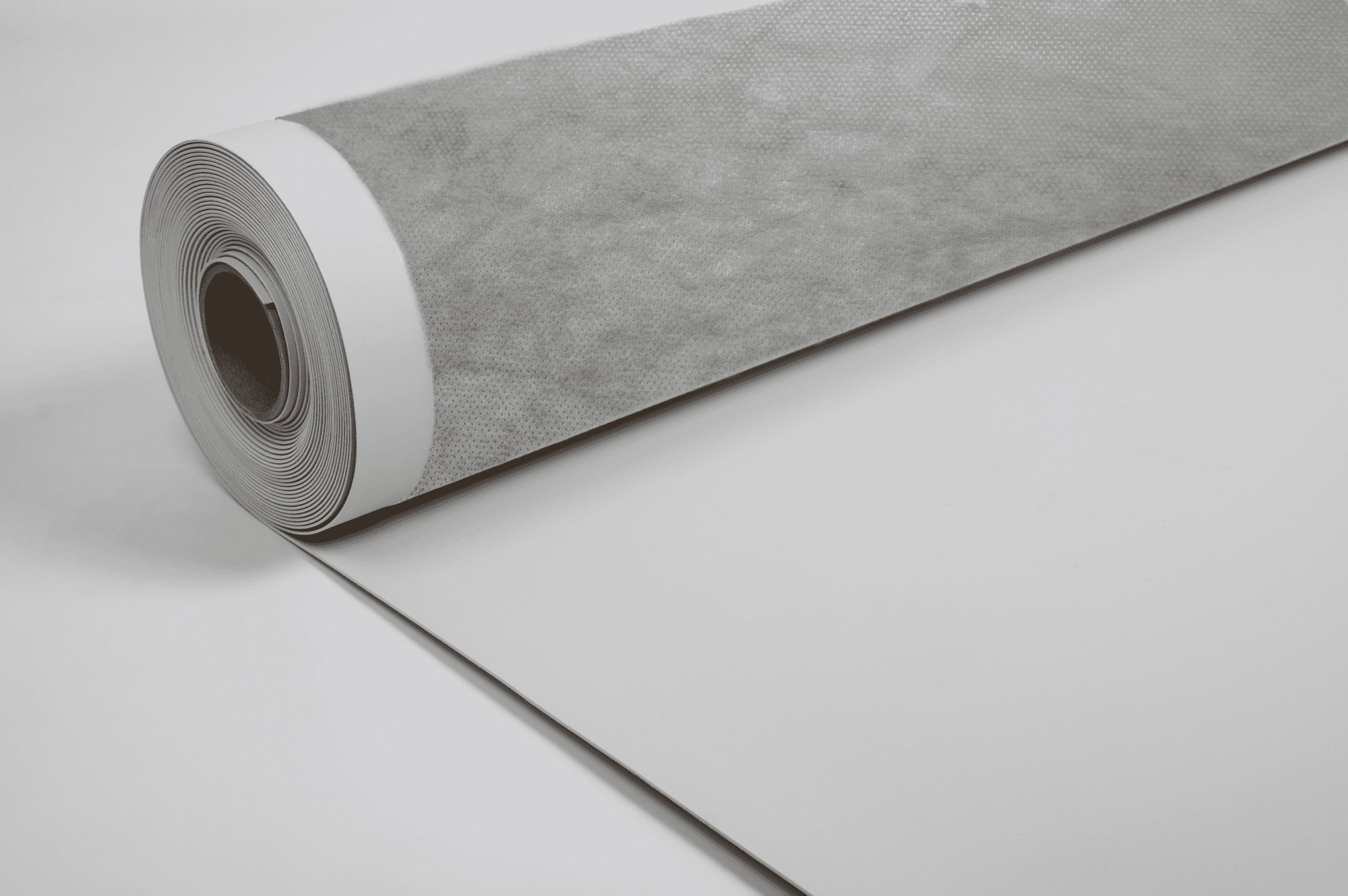

Processing & Protective Films for Roofing Membranes

Among the different existing waterproofing roofing solutions, membrane products have been, and continue to be viable product options versus traditional alternatives.

With more than 42% growth in the past 10 years, the membrane products have gained industry acceptance.

Their naturally reflective surfaces reflect UV rays, lowering energy costs. On top of it, roofing membranes are lighter, faster to install and less expensive than classic roofing products.

Download our catalogue of processing and protective films for roofing membranes!

Films for EDPM - TPO & PVC

During installation, roofing membranes can get dirty or damaged by foot traffic, dropped tools, ladders, or other installation accessories present on the roof.

In order to guarantee a high-level performance, and improve the installers’ efficiency, it is essential to protect the membranes from their production to their installation. It also contributes to cost savings by keeping the surfaces perfectly clean to the end.

All Novacel products have been developed with and for membranes’ manufacturers to propose a complete and effective solution.

However, as membranes formulations are company specific, Novacel R&D team always provides a systematic technical support to fit the most suitable solution.

All the Novacel assets in the Membranes range

Quality, efficiency and safety

- Perfect adhesion on the surface

- Automatic lamination in-line or off-line

- No tearing during removal

- No stains or residues left

- All weather-proof and high temperatures resistant worldwilde

- Easy membrane unwinding, no liner needed

- Easy film removal, one man only

- Special formulated backing film to reduce slipping when working on roof

Fleece backed Membranes

In addition to traditional roofing membranes, a fleece backing layer can be laminated to the roof side for insulation purpose.

As membranes are rolled up, this fleece layer can stick to the top of the surface and therefore jeopardize its integrity.

Novacel Expertise on fibered and textile surfaces enable us to propose solutions for those applications.

Release coating for self adhesive membranes

As safety and time are two major concerns for companies and installers, self-adhesive roofing membranes are being developed on the market.

This adhesive coating requires a release solution in order to roll the membrane up without jeopardizing its technical condition and integrity.

A specific solution for site construction safety

Novacel 9573, has been specially developed for construction site safety, it has been designed with a special backing with anti-slip properties.

Thanks to the different options with adhesive levels to cover all needs, like Novacel 4235, and Novacel 4324, there can be no doubt that the right Novacel solution is available for your application.

Where very specific applications with technical and climatic constraints, it is imperative to ask Novacel for a recommendation.